We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

We understand the challenges of various industries, and manufacture reliable quality products through top-notch equipment and professional production technology, so that customers' ideas can be quickly realized.

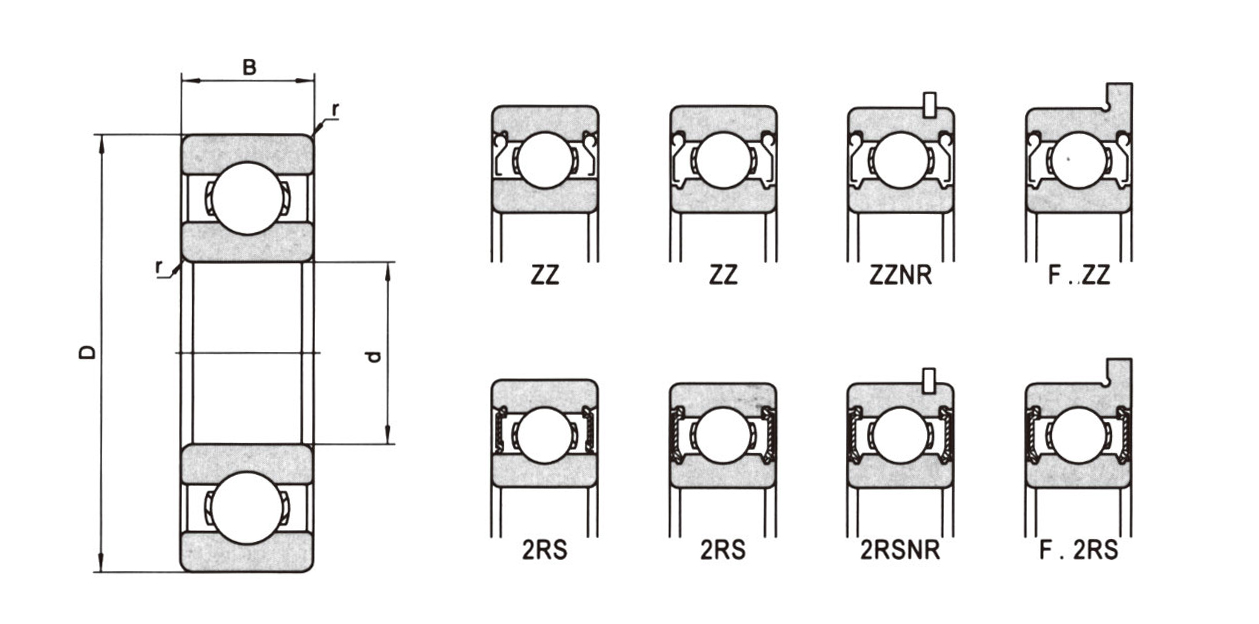

| Bearing type | Diameter size | Rated load | Reference weight (closed) kg |

|||||

| Inner diameter d mm inch |

Outer diameter D mm inch |

Width B | Chamfer rsmin mm inch |

Dynamic load Cr N |

Static load Cr N |

|||

| Open type | Closed type | |||||||

| mm inch | mm inch | |||||||

| 693 | 3 0.1181 | 8 0.3150 | 3 0.1181 | 4 01575 | 0.15 0.006 | 430 | 170 | 0.0008 |

| 694 | 4 0.1575 | 11 0.4331 | 4 0.1575 | 4 0.1575 | 0.15 0.006 | 960 | 350 | 0.0017 |

| 695 | 5 0.1969 | 13 0.5118 | 4 0.1575 | 4 0.1575 | 0.2 0.008 | 1070 | 420 | 0.0023 |

| 696 | 6 0.2362 | 15 0.5906 | 5 0.1969 | 45 0.1969 | 0.2 0.008 | 1470 | 600 | 0.0036 |

| 697 | 7 0.2756 | 17 0.6693 | 5 0.1969 | 5 0.1969 | 0.3 0.012 | 1600 | 710 | 0.005 |

| 698 | 8 0.3150 | 19 0.7480 | 6 0.2362 | 6 0.2362 | 0.3 0.012 | 2230 | 910 | 0.0076 |

| 699 | 9 0.3543 | 20 0.7874 | 6 0.2362 | 6 0.2362 | 0.3 0.012 | 2480 | 1090 | 0.0085 |

| 6900 | 10 0.3937 | 22 0.8661 | 6 0.2362 | 6 0.2362 | 0.3 0.012 | 2690 | 1270 | 0.01 |

| 6901 | 12 0.4724 | 24 0.9449 | 6 0.2362 | 6 0.2362 | 0.3 0.012 | 2890 | 1460 | 0.012 |

| 6902 | 15 0.5906 | 28 1.1024 | 7 0.2756 | 7 0.2756 | 0.3 0.012 | 4320 | 2250 | 0.018 |

| 6903 | 17 0.6693 | 30 1.1811 | 7 0.2756 | 7 0.2756 | 0.3 0.012 | 4590 | 2550 | 0.19 |

| 6904 | 20 0.7874 | 37 1.4567 | 9 0.3543 | 9 0.3543 | 0.3 0.012 | 6370 | 3680 | 0.038 |

| 6905 | 25 0.9843 | 42 1.6535 | 9 0.3543 | 9 0.3543 | 0.3 0.012 | 6660 | 4180 | 0.044 |

| 6905 | 30 1.1811 | 47 0.18504 | 9 0.3543 | 9 0.3543 | 0.3 0.012 | 7240 | 5010 | 0.05 |

| 6907 | 35 1.3780 | 55 2.1654 | 10 0.3937 | 10 0.3937 | 0.6 0.024 | 10390 | 7160 | 0.75 |

| 6908 | 40 1.5748 | 62 2.4409 | 12 0.4724 | 12 0.4724 | 0.6 0.0.24 | 10320 | 9200 | 0.118 |

| 6909 | 45 1.7717 | 68 2.6772 | 12 0.4724 | 12 0.4724 | 0.6 0.024 | 13490 | 10130 | 0.128 |

| 6910 | 50 1.9685 | 72 2.8346 | 12 0.4724 | 12 04724 | 0.6 0.024 | 13900 | 10990 | 0.133 |

| 6911 | 55 2.1654 | 80 3.1496 | 13 0.5118 | 13 0.5118 | 1 0.039 | 14820 | 12690 | 0.177 |

| 6912 | 60 2.3622 | 85 3.3465 | 13 0.5118 | 13 0.5118 | 1 0.039 | 15080 | 13480 | 0.191 |

Ningbo Xiaoerma Bearing Co., Ltd. is a professional China 6900 Series Deep Groove Ball Bearings Manufacturers and 6900 Series Deep Groove Ball Bearings Factory. With craftsmanship, advanced equipment, comprehensive testing methods, and a high-quality technical development team, as well as skilled and efficient employees, the company is dedicated to maintaining a focus on quality throughout every aspect of its operations, from raw material selection to production and manufacturing, and from performance testing to final inspection. This ensures that every set of products leaving the factory meets market demands. The company has obtained ISO9001 international system certification, and its products are widely applied in household appliances, industrial motors, and other fields. Ningbo Xiao Erma Bearing Co., Ltd. adheres to the principle of "Integrity and pragmatism, harmony and win-win" and follows the business philosophy of "pioneering and innovative, customer-oriented". The company sincerely looks forward to cooperating with more customers and friends, hand in hand, for mutual progress. They wholeheartedly hope to engage in sincere cooperation with customers at home and abroad, and achieve development together!

In the vast universe of industry and machinery, 6000 series deep groove ball bearings have become an indispensable "heart" component in many mechanical equipment with their excellent performance and w...

READ MORE6000 Series Deep Groove Ball Bearings are widely used in many industrial fields, but vibration and noise problems may affect their performance and the overall operation of the equipment. To solve thes...

READ MOREThe sealing technology of 6000 Series Deep Groove Ball Bearings plays a vital role in preventing contamination and leakage.Its sealing technology adopts a high-precision sealing structure design. Comm...

READ MOREWhat lubrication methods are recommended for 6900 Series Bearings?

Lubrication is a critical aspect of ensuring optimal performance and longevity of bearings in various industrial applications. When it comes to the 6900 Series Bearings, selecting the right lubrication method is essential to maximize efficiency and minimize wear.

One of the primary lubrication methods recommended for 6900 Series Bearings is grease lubrication. Grease offers several advantages, including ease of application, retention within the bearing, and protection against contamination. When selecting grease for 6900 Series Bearings, factors such as operating temperature, speed, and load should be taken into consideration. High-quality, lithium-based greases with EP (extreme pressure) additives are often preferred for their ability to withstand high loads and temperatures while providing adequate lubrication.

Another lubrication method commonly employed for 6900 Series Bearings is oil lubrication. Oil lubrication offers superior cooling and flushing capabilities compared to grease, making it suitable for high-speed applications or environments with elevated temperatures. When using oil lubrication, proper viscosity selection is crucial to ensure adequate lubrication film thickness and minimize friction. Additionally, oil lubrication systems may require more intricate design and maintenance compared to grease lubrication systems but offer greater flexibility in controlling lubricant flow and replenishment.

In some cases, a combination of grease and oil lubrication, known as hybrid lubrication, may be employed for 6900 Series Bearings. Hybrid lubrication combines the benefits of both grease and oil, providing excellent lubrication properties while enhancing sealing and contamination resistance. This approach is particularly advantageous in applications where periodic re-lubrication is challenging or where the operating conditions vary significantly over time.

The frequency and method of lubrication for 6900 Series Bearings depend on various factors, including operating speed, load, temperature, and environmental conditions. In general, regular lubrication intervals should be established based on manufacturer recommendations and operating conditions to ensure proper lubrication film thickness and prevent premature wear or damage to the bearings.

In addition to selecting the appropriate lubrication method, proper lubricant storage and handling are essential to maintain lubrication effectiveness and prevent contamination. Lubricants should be stored in clean, sealed containers and kept away from moisture, dirt, and other contaminants. Before applying lubricant to the bearings, it's essential to clean the bearing housing and surrounding components to remove any debris or old lubricant residue that could compromise performance.

Furthermore, monitoring lubricant condition and bearing performance is crucial to identifying potential issues early and preventing costly downtime. Regular inspections should include checking for signs of lubricant degradation, contamination, or insufficient lubrication, such as abnormal noise, vibration, or increased operating temperature. Any abnormalities should be addressed promptly, and lubricant replenishment or replacement should be performed as needed to maintain optimal bearing performance.

Selecting the right lubrication method is essential for maximizing the performance and longevity of 6900 Series Bearings in various industrial applications. Whether using grease, oil, or a combination of both, proper lubrication practices, including regular maintenance, monitoring, and lubricant selection, are vital to ensuring smooth operation and minimizing wear and tear on the bearings.